Single-disc drills TURBOSEM

Turbosem air-drill is a multi-functional seeding machine, which is intended for direct seeding.

- It performs uniform seed placement due to the opener's design, which allows to follow the soil contour.

- The machine can place seeds regardless of previous soil tillage (conventional, mini-till and no-till).

- Suitable for different crops: cereals, small grains, row-crops.

- This machine is capable of applying dry fertilizers together with seeds and separately.

- Mobile and portable drills Turbosem 19-16, 19-32 and Turbosem 19-40 feature low energy consumption. Thus, they can be pulled by tractors with a horsepower rating starting from as low as 100 h.p. This is an ideal solution for small farms.

Turbosem drills feature high capacity and cost effectiveness along with simplicity and convenience in maintenance and use.

There are two types of Turbosem drills: wide drills Turbosem II (11.4 and 9.12 meters wide) and a compact drills Turbosem (3, 6 and 7.63 meters wide).

The opener of Turbosem drill is represented by a single-disc opener, which creates a V-furrow to place seeds and fertilizer with minimum soil disturbance.

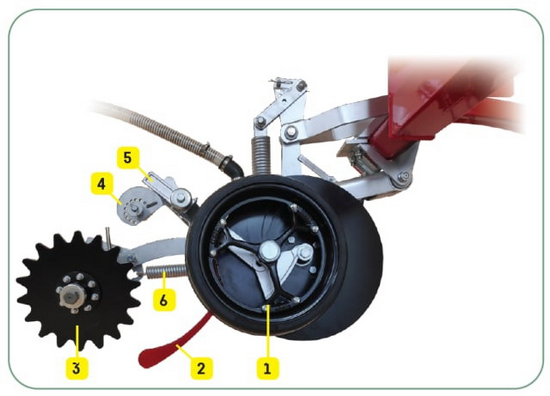

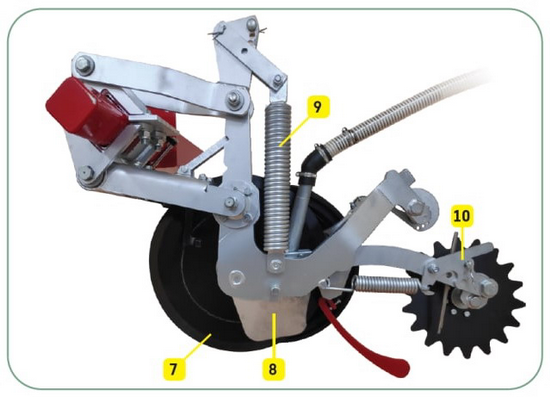

The open gauge wheel (1) follows field undulations through parallel linkage. The disc (7) and the hoe (8) cut the V-furrow in the soil. These are made of high-quality boron steel and feature high wear-resistance. The disc runs at 11° angle to the machine’s longitudinal axis.

The permanently closed hoe is spring-pressed against the disc. Seeds are pressed into the soil by means of a firming device (2), which is made of polymer material, featuring flexibility and wear-resistance. Finally, the closing wheel (3) running behind the disc, closes the seeds with loose soil.

The wheel’s teeth break compacted wall, which occurs upon cutting the soil by the disc. The down-pressure and the angle of attack of a closing wheel can be adjusted by a spring (6) and an adjusting bar (10).

The down-pressure can be adjusted by a spring (9) from 80 to 200 kg. The gauge wheel rests on the eccentric cam (4) via the arm (5). Thus, the seeding depth can be adjusted from 1 cm to 11 cm. The increment of adjustments is 1 cm.

The opener is attached to the toolbar via the parallel linkage. This maintains continuous uprightness in relation to the soil during ground following. The hoe is aligned with a support gauge wheel, which ensures ideal ground following to maintain depth uniformity in the process of seed and fertilizer placement.

Initially developed for grain crops this model can also seed row-crops. This option is realized due to a technological solution – blocking of every other opener and a possibility to move the front row of openers for split fertilizer application (sideways and under the seeds).

The open gauge wheel (1) follows field undulations through parallel linkage. The disc (7) and the hoe (8) cut the V-furrow in the soil. These are made of high-quality boron steel and feature high wear-resistance. The disc runs at 11° angle to the machine’s longitudinal axis.

The permanently closed hoe is spring-pressed against the disc. Seeds are pressed into the soil by means of a firming device (2), which is made of polymer material, featuring flexibility and wear-resistance. Finally, the closing wheel (3) running behind the disc, closes the seeds with loose soil.

The wheel’s teeth break compacted wall, which occurs upon cutting the soil by the disc. The down-pressure and the angle of attack of a closing wheel can be adjusted by a spring (6) and an adjusting bar (10).

The down-pressure can be adjusted by a spring (9) from 80 to 200 kg. The gauge wheel rests on the eccentric cam (4) via the arm (5). Thus, the seeding depth can be adjusted from 1 cm to 11 cm. The increment of adjustments is 1 cm.

The opener is attached to the toolbar via the parallel linkage. This maintains continuous uprightness in relation to the soil during ground following. The hoe is aligned with a support gauge wheel, which ensures ideal ground following to maintain depth uniformity in the process of seed and fertilizer placement.

Initially developed for grain crops this model can also seed row-crops. This option is realized due to a technological solution – blocking of every other opener and a possibility to move the front row of openers for split fertilizer application (sideways and under the seeds).

| Specifications | Turbosem II 19-60 | Turbosem II 19-48 | Turbosem 19-40 | Turbosem 19-32 | Turbosem 19-16 |

| Working width, m | 11,4 | 9,12 | 7,63 | 6 | 3 |

| Number of rows with openers | 2 | 2 | 2 | 2 | 2 |

| Number of seeding openers | 60 | 48 | 40 | 32 | 16 |

| Distance between openers, m | 0,19 | 0,19 | 0,19 | 0,19 | 0,19 |

| Tank volume, liters | 10 500 | 10 500 | 7 500 | 7 500 | 5700 |

| Tank sections ratio (fertilizer/seeds) | 60/40 | 60/40 | 60/40 | 60/40 | 60/40 |

| Type of fertilizer | Dry/Liquid | Dry/Liquid | Dry/Liquid | Dry/Liquid | Dry/Liquid |

| Transport width, m | 5,50 (3,64 - wheel track) | 5,50 (2,714 - wheel track) | 4,35 (2,23 - wheel track) | 4,35 (2,23 - wheel track) | 3,0 (2,32 - wheel track) |

| Transport height, mм | 5,25 | 4,15 | 3,96 | 3,96 | 3,1 |

| Weight of the machine (w/o the tank), kg | 11 900 (без бункера) | 10 330 (без бункера) | 10 500 | 9 750 | 3200 |

| Recommended seeding speed, km/h | 8-9 | 8-9 | 8-9 | 8-9 | 8-9 |

| Required tractor power, h.p. | 310-330 | 250-280 | 200 | 150-180 | From 100 |